Mechanical Filter

The Pre-filters can either be panel filters (mechanical filter) for removing dust, or inertial maze filters (active filters) with their own fans. As the mixture of dust and air enters the inertial, most of the air changes direction, separating itself from the dust as it passes through the vanes. The particles above 2um will be separated with 98% efficiency.

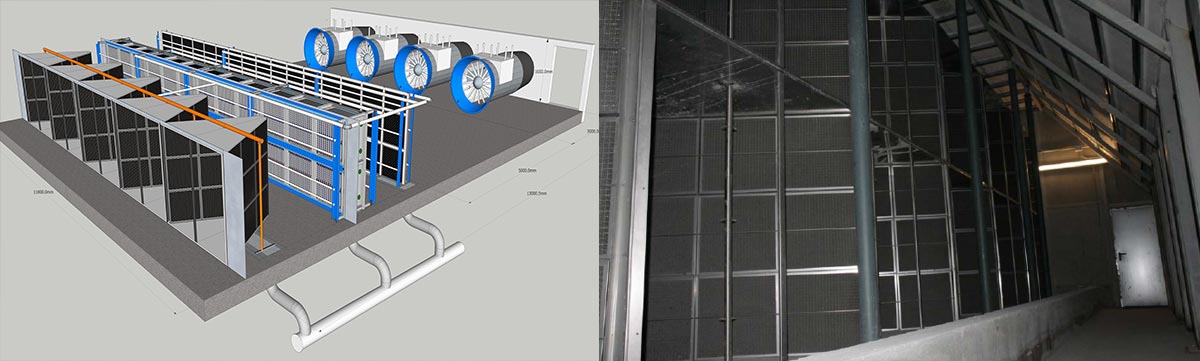

Electrostatic Precipitator

The corona shown at one section of the EP is generated by the CTA's High Efficiency.

Spike Ionizer System

The Electrostatic Precipitator cell is built from stainless steel and aluminum. The EP-System is built of a modular design. The filter array can fill the entire cross section of the bypass tunnel to provide maximum efficiency versus velocity. The fine dust particles pass through a strong electrostatic field where they are electrically charged. In the subsequent collector with interleaved plates, the charged particles accumulate while the cleaned air passes through with little pressure drop.

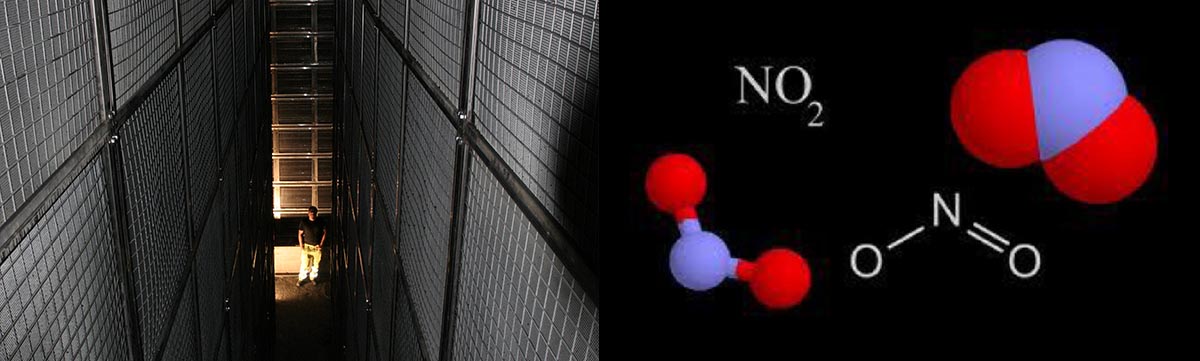

NO2 Gas Removal System

CTA used special activated carbon filter to removing NO2 with above 80% efficiency. It’s using absorption method, safely and reliable. Use the explanation from Norit here.

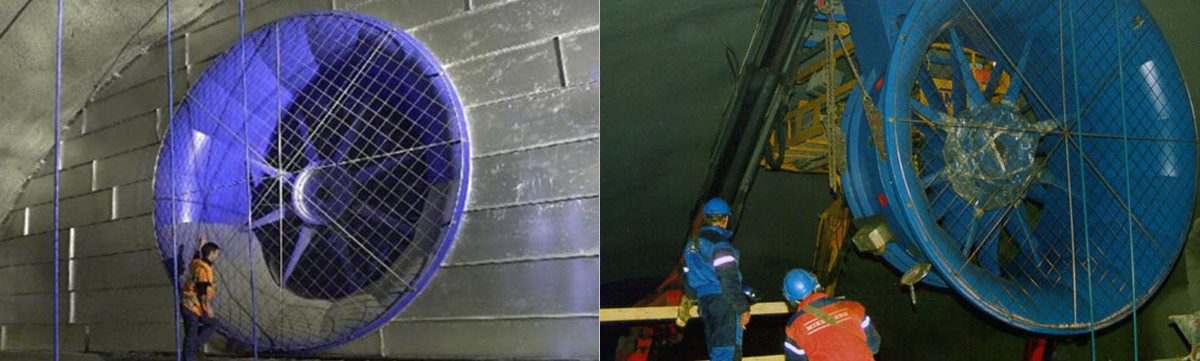

Axial Fans

The axial fans in each system draw polluted air from the tunnel into the filter system and returns cleaned air to the tunnel. We are using very big axial fans, which not only saves running cost, but also gives us a more uniform air profile over the filter banks and a stable efficiency.

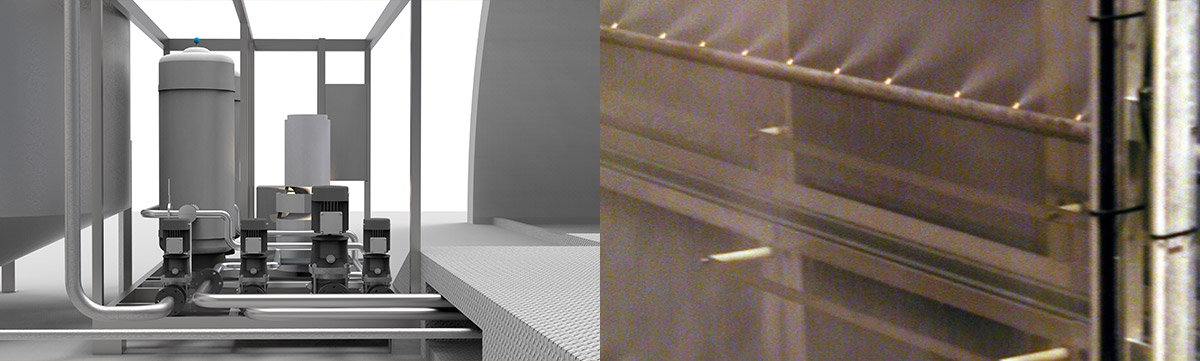

Automatic Washing System

The washing system consists of water- and detergent supply tank, a water pump system, a dosing pump for detergents as well as a pipe distribution system for the correct washing of the electrostatic filters. CTA delivers its own produced detergent that is environmentally friendly.

After the automatic washing of the filters, the dirty water is either conducted to its own sedimentation tank or it can be re-used by using the wastewater recycling system.

Waste Water Recycle System

Water regeneration package is based on well proven technology, is mechanically simple and its operation may be fully automatic performed based on remote surveillance。The waste water treatment system is divided into two parts and re-circulates the contaminated water that comes back from the automatic washing process. The system is compact and includes both a feed and a return tank. The tanks are dimensioned with reference to the water needed for the automatic cleaning of the electrostatic filters. It can remove 99.9% of all pollution from the water. 2 patented electrolysis units remove 100% of all chemicals used during washing. Its compact size brings less installation cost and easy-to-fit.

Control System

CTA delivers power supply cabinets for the application and one main control cabinet. The main control cabinet includes a PLC for all system functions. The automation systems are simple to use, minimize energy costs and are flexible. This enables CTA to customize the automation system to the individual needs of the end-user.